Table of Contents

ToggleFrom waste to low-carbon resources, ESG sustainable practices are implemented in Jinsu Factory

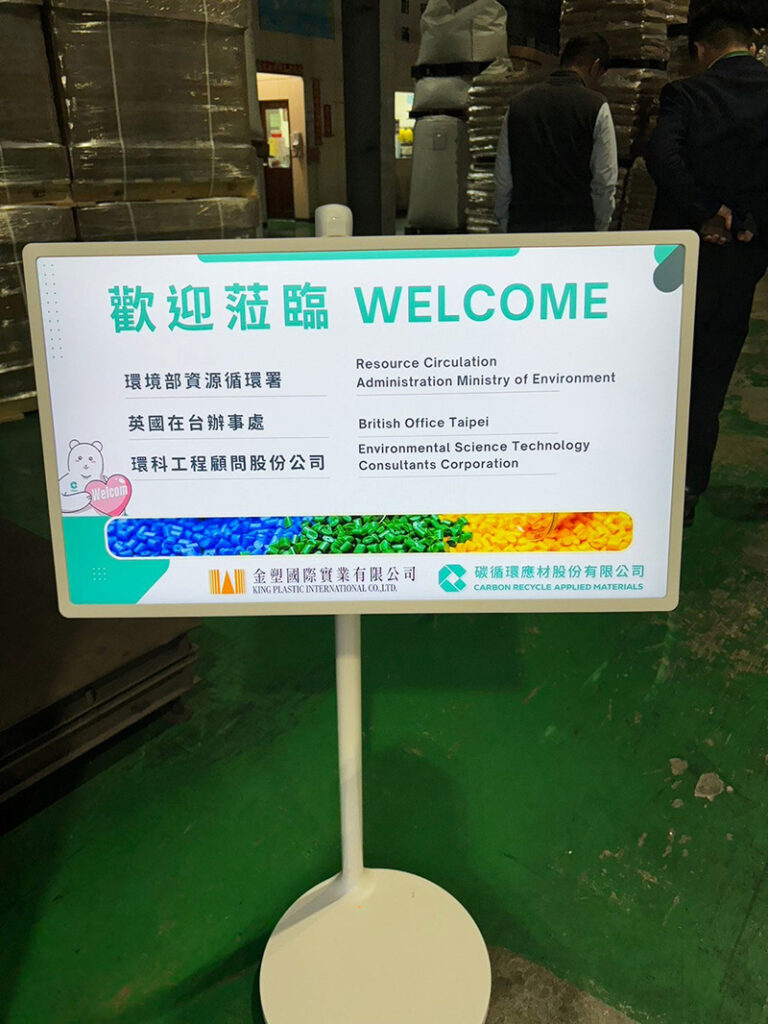

On February 26, 2025, the British Office in Taiwan, the Ministry of Environment's Resource Recycling Department and the Environmental Engineering Consultants visited the Carbon Recycling Materials (CRAM) Recycling Cascade Factory (shareholder) - Jinsu International Industrial Co., Ltd.Limited Company (Low carbon cyclePlasticRubber granulation plant).

Witness first-hand how Taiwan transforms waste into high-value resources.

During the factory visit, CRAM demonstrated its plastic recycling, disassembly, purification, and regeneration.RecyclingThe key technology for processing more than 55,000 tons of plastic waste each year was revealed. Guests also witnessed the recycling of plastic pellets from waste home appliances into plastic products that meet the requirements ofCBAM EUNormativePCR plasticThe carbon footprint of the new material is only 1/10, which amazed the international delegation.

The British representative was even more amazed: "Taiwan's average plastic recycling rate is so high (About 50%), far exceeding the international average plastic recycling rate (9%)

The process secrets snapped up by the Ministry of Environment: Why can the EU pay for CRAM recycled materials?

CRAM led the delegation to see how waste plastic crushing materials go through multiple stages of purification, full physical property testing, melting pipes, plastic granulation, etc.Plastic RecyclingProcess.

Ministry of Environment officials are particularly concerned about the recycling of feedstockProduction and reuseDuring production, we have gone through the "full physical inspection and quality inspection return at each stage" mechanism - from tracing back the source of recycled raw materials, monitoring the physical properties of the process to the finished productCarbon Footprint Certification, ensuring that each batch of materials meetsTUVpairCertification(ISO14021/14067).

From routers to IC trays, CRAM helps companies reduce carbon emissions

Highlights of the visitCRAMWith Australian telecommunications giantsCarbon reductionSpecial case:

CRAMLaunch cross-border productsClosed loop: Cooperate with Australian telecommunications operators to help them recycle electronic housings in Australia, dismantle and crush them, and then ship them to Taiwan. After tempering, they are added with recycled water bottles and wafer boxes from Taiwan to becomePCR low carbon recycling materials, and returned to their factories to be manufacturedlow carbonThe router casing was put back on the market, successfully realizing the cross-border product closed cycle of "recycling in Australia - regeneration in Taiwan - local manufacturing".

This case is a cross-bordercircular economyA classic demonstration of Taiwan's internationalcircular economyThe important role of chain.

CRAMThe CEO stressed: “We are not just sellingLow carbon materials, and also providesCarbon reductionDiagnosis service. "

Pictured from right to left: British Office in Taiwan: Shyam Desai – Head of Economic Section; Recycling Department: Lai Yingying; Carbon Cycle Applied Materials CEO Lin Xuanlong

For example: Assisting the electronics industry toPCR plasticThe ratio is increased from 30% to 70%, while maintaining fireproof and impact-resistant properties, breaking the "Environmentally friendly materials=Low quality” myth.

in additionCRAMIt also starts the internal circulation of the enterprise: after the scraps are recycled, the scraps are controlled, processed, crushed, purified, granulated and inspected, they becomerecycled plastic, thereby reducing waste,Reduce carbon emissions in the production process.

For example:CRAMFor Taiwan semiconductor manufacturers, discarded IC Trays were broken up and remade into high-qualityLow carbon footprintPlastic pellets are used to manufacture new products.

Stop greenwashing! Transparent traceability is the key to ESG trust

Facing the worldGreenwashing"dispute,CRAMShow its production history traceability system: each packagePCR materialsEach comes with a unique QR Code to track the source of the material, the recycler, and evenCarbon emissionsdata. A representative of Environmental Science Consulting pointed out: "This transparency is precisely the advantage of Taiwan's supply chain in entering the international market, and it is also in line withEU CBAMrightDigital Product PassportDPP and EUSustainable ProductsEco-design regulations "ESPR requirements".CRAMFurther disclosure: "PCR low carbon materialThe system will provide order-level traceability services, allowing enterprises to instantly check the purchased goods through their exclusive order numbers.PCR low carbon recycling materialsRecycling sources, recycling processes and third-party verification data to ensure complianceEuropean UnionCSRD (Corporate Sustainability Reporting Directive) andCarbon Border Adjustment Mechanism (CBAM)Standardization for business successLow carbon transition, expand the European market and provide strongESGCompliance support.

Looking ahead to a net-zero emissions future, CRAM launches sustainable fleet plan

CRAMAnnounced that it will connect 20 small and medium-sized recycling plants to create a "Sustainable CycleFleet Alliance, through technology licensing andcarbon rightsSharing and expanding Taiwan’s waste treatment capacity. The Ministry of Environment affirms this model: "From a singleCorporate carbon reductionUpgrading to an industrial ecosystemCarbon reduction, which is exactly what Taiwan has achieved2050 Net Zero Emissions Targetkey strategies. "

Conclusion

CRAMThank you to the three organizations for their guidance and emphasize that they will continue to play a role in Taiwan and multinational companies.ESG low-carbon transformation's promoter. As the British representative said: "This factory visit proves that Taiwan'scircular economyStrength is rewriting the worldSustainablerule. "