Sustainable aluminum industry is imperative

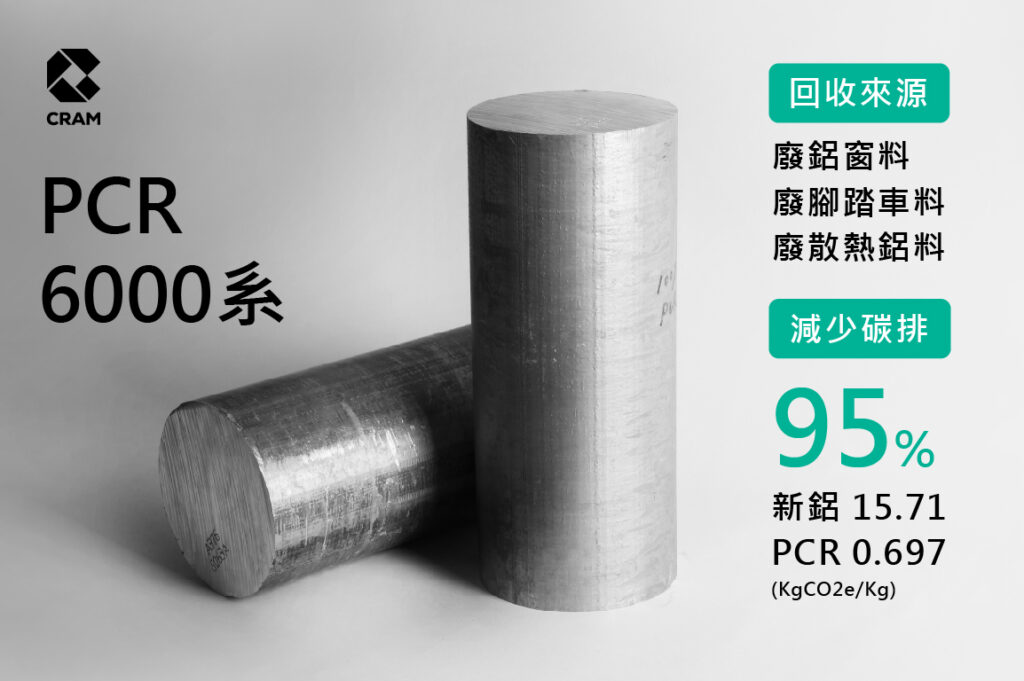

According to the International Aluminum Association (IAI), recycling aluminum requires "95%" less energy than producing primary metal. Producing primary metal requires approximately 14 megawatt hours (kW·h) of electricity per ton, while recycled aluminum requires only 0.7 kWh. Watt hours of electricity.

Although the British Geological Survey (BGS) stated that aluminum ranked second among all metals mined in 2019, after iron, with a total of 62.9 million tons mined, data confirms that this light non-ferrous metal ( Non-ferrous metals) have the highest emission intensity per dollar (kgCO2/$) of all metals.

Therefore, it is easy to imagine that using bauxite to produce this metal wastes energy and natural resources on the one hand, and produces pollution on the other. Because producing it requires a complex process: Mined bauxite is a clay that needs to be cleaned, ground, and then the aluminum extracted from the bauxite or refined, and finally processed into various products.

On the other hand, a large amount of aluminum still ends up in landfills every year, which means environmental damage and pollution because this material takes hundreds of years to break down, so we need to recycle more aluminum to be truly sustainable.

Decisive advantages of recycled aluminum

1. Features of unlimited recycling:

Aluminum's crystalline structure makes it very easy to become a solid when melted without changing its basic properties. This means aluminum can be recycled over and over again, with no theoretical limitations.

2. Saving and environmental protection:

Using recycled aluminum is a more energy-saving option than extracting pure aluminum (making new aluminum). The energy consumed can be reduced by approximately 90%. The main reason is that the electrolytic aluminum process when extracting pure aluminum requires a lot of power.

3.Industrial development:

The global investment rate of recycled aluminum is about 32%, while in the United States it is as high as 57%. However, the proportion of recycled aluminum application in my country is only 36%. This shows that Taiwan's recycled aluminum market still has a lot of room for development!

The explanation of “infinitely recyclable”

Like all metals, all materials lose some volume during the melting and recycling process, but in the case of metals, the material itself does not degrade. In the case of aluminum, there is usually a small amount of metal lost through milling operations or oxidation.

Although the melt loss is minimal, the basic properties remain unchanged and can be recycled again and again. Of all the aluminum produced to date, nearly 75% is still in use today.

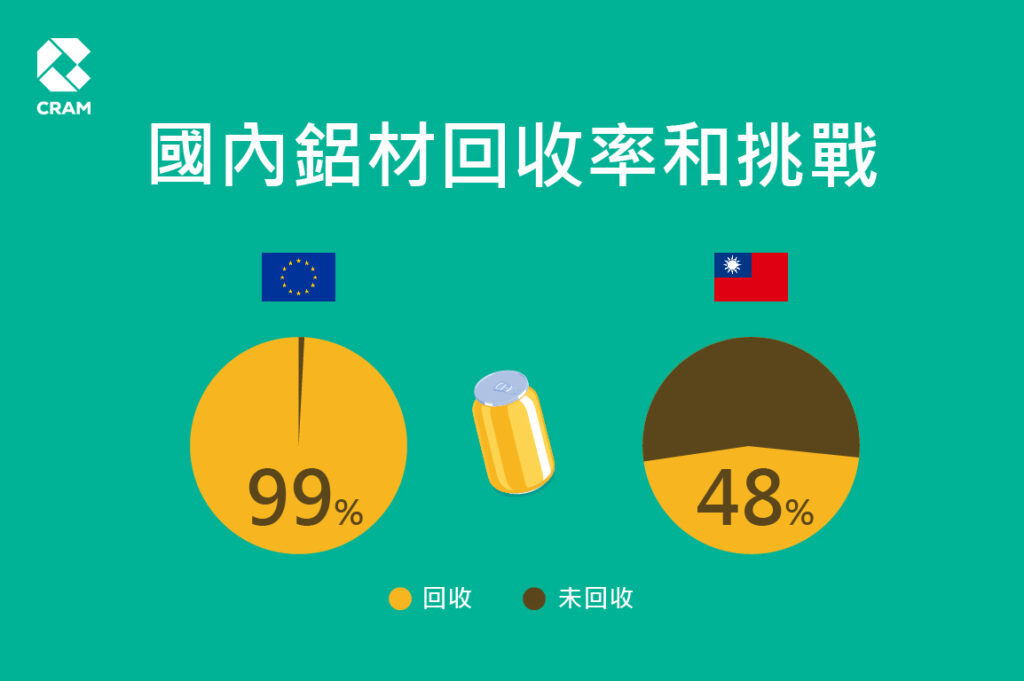

Domestic aluminum recycling rates and challenges

Although some countries have achieved excellent recycling results, aluminum recycling rates are also an important issue.

According to 2018 statistics, in Europe, the recycling rate of aluminum beverage cans in Germany reached 99%, while in Belgium and Lithuania, the recycling rates of aluminum cans were 98% and 96% respectively. In contrast, according to statistics from the Ministry of Environment of my country, the recycling rate (recycling volume/business volume) of scrap aluminum containers is only 46-48%. This shows that more efforts are needed to increase aluminum recycling rates to achieve sustainable development.

CRAM Carbon Cycle Applied Materials’ Sustainable Low-Carbon Aluminum

Recycling aluminum is a key step in maintaining environmental sustainability. The professional team of CRAM Carbon Recycling Materials has focused on the circular economy of aluminum metal for more than 40 years. We have extensive experience in the production of PCR recycled aluminum and quality control of aluminum recycling sources, and can assist Enterprises create internal cycles of products.

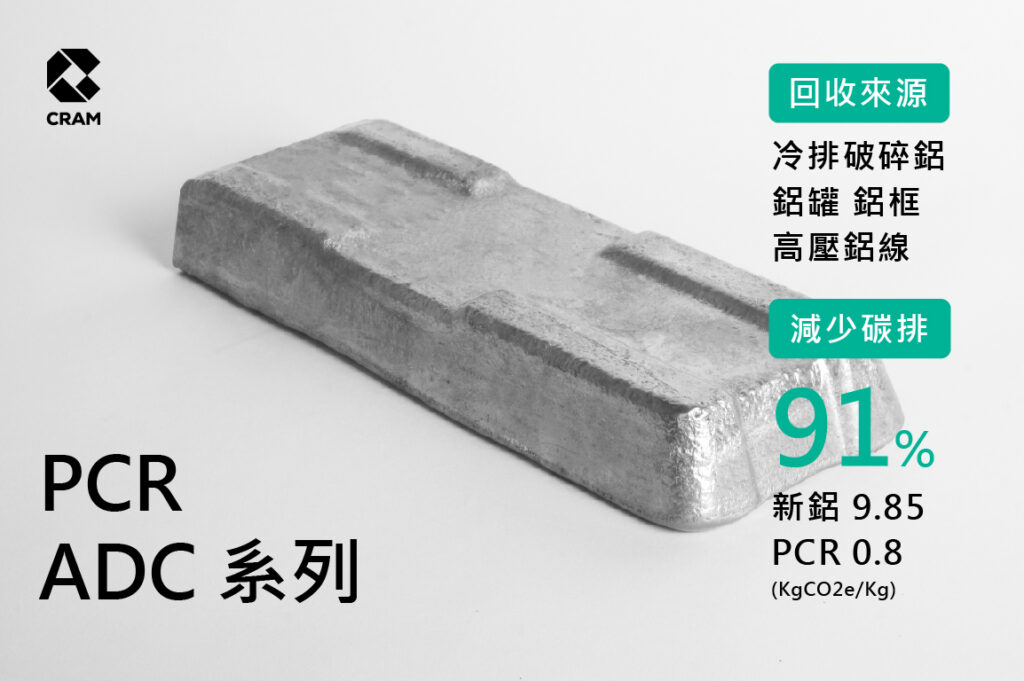

The low-carbon recycled aluminum alloys currently developed include ADC series, 6000 series, etc. The materials are all traceable and have carbon footprint calculations. They have been verified by the internationally renowned TÜV Rheinland, including green and environmentally friendly material verification (ISO14021) and carbon footprint verification. (ISO14067).

PCR Recycled Aluminum 6000 Series Aluminum Extrusion

PCR Recycled Aluminum ADC Series Die Casting Aluminum

We use professional planning for our customers and are committed to achieving the "best carbon reduction effect" and "physical stability" solutions, all of which come from the detailed control of every step; by using recycled aluminum, we can significantly reduce energy consumption , reduce pollution, and promote the practice of green manufacturing.

We will continue to be committed to providing high-quality, low-carbon recycling materials and work with you to achieve sustainability goals!