- Lin Xiu/Taipei DIGITIMES

- 2024/11/22 10:55

More than 90% of Taiwan's businesses are small and medium-sized enterprises. In the global supply chain system, they manufacture for international brands and face tremendous pressure to reduce carbon emissions. Taiwan's Ministry of Environment's Resource Recycling Administration and Circular Economy Promotion Office and other government departments have gradually improved low-carbon economic policies to promote low-carbon industrial transformation and reduce carbon emissions.

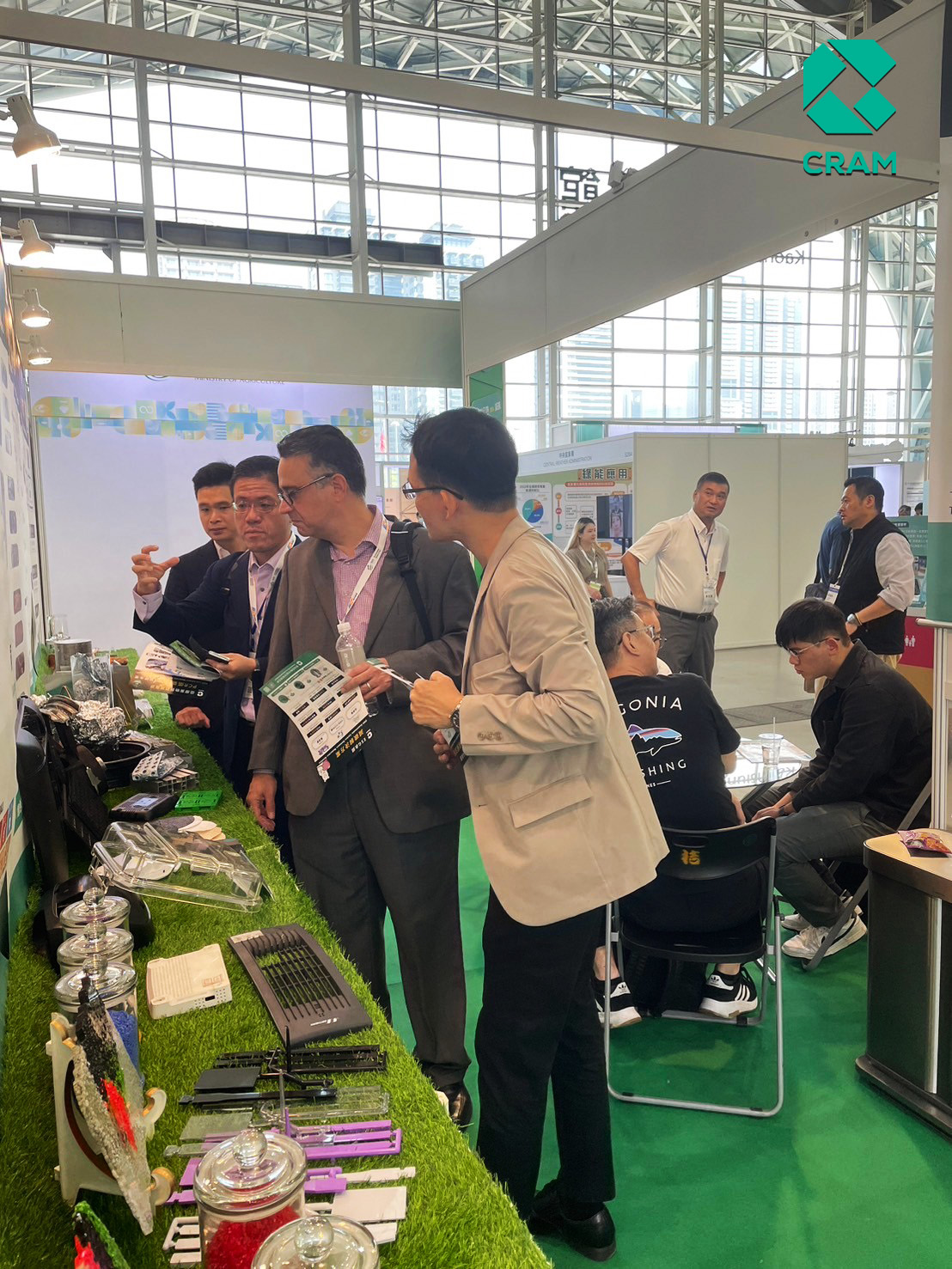

From November 6th to 8th, the 2024 TASS Asia Sustainable Supply + Circular Economy Exhibition was grandly held at the Kaohsiung Exhibition Hall. This is an important platform to connect circular industry resources and stimulate ESG innovative practices. Carbon Recycling Materials Co., Ltd. (CRAM), as a pioneer in PCR (Post-Consumer Recycled) recycling materials, takes this opportunity to showcase the latest recycling low-carbon technology and carbon reduction solutions.

During the exhibition, CRAM's booth attracted many VIPs from manufacturing plants, injection molding plants, consulting companies and related industries. These companies have a deep understanding and demand for ESG. Many visitors from the manufacturing industry reported that carbon reduction and sustainability are no longer distant ideals, but necessary conditions for enterprise development. Especially in the supply chain, as Taiwanese and foreign brands have successively increased their requirements for supply chain carbon reduction, more and more manufacturers need to use low-carbon footprint recycled materials to reduce product carbon emissions and carry out industrial low-carbon emissions. Carbon transition. There are a large number of companies with strong interest in low-carbon materials and recycling technologies gathered around the CRAM booth, which proves the deep demand and broad market space for the low-carbon recycling industry.

During the TASS exhibition, CRAM had in-depth exchanges with visiting distinguished guests and deeply felt that manufacturers are in urgent need of low-carbon product solutions to transform into sustainable supply chains. Carbon Cycle Application Materials summarizes 5 key points of manufacturers’ low-carbon transformation needs:

1. Sustainable sources of low-carbon materials: Manufacturers are looking for stable, certified sources of low-carbon recycling materials to meet brand owners’ requirements for sustainable supply chains and increasingly stringent carbon emissions and environmental regulations.

2. Carbon footprint transparency: Brands and manufacturers need to comprehensively track the carbon footprint of their products and provide transparent carbon emissions information throughout the supply chain to meet the dual requirements of consumers and regulations.

3. Closed recycling system: In order to achieve the goal of net-zero transformation, companies need a closed cycle system that can efficiently recycle waste materials and regenerate them into new materials, thereby reducing resource consumption and enabling multiple recycling of materials.

4. Standard-compliant low-carbon certification: More and more brands and customers require suppliers to provide third-party low-carbon certification (such as TUV certification) to ensure that their materials and products meet environmental standards.

5. Low-carbon material technology innovation: Enterprises urgently need advanced low-carbon material technology to cooperate in the research and development of low-carbon products, ensure product quality, and reduce carbon emissions in the difficult category 3 of carbon inventory.

Professional consulting services for low-carbon products

The uniqueness of CRAM is that it not only provides high-quality PCR (Post-Consumer Recycled) low-carbon materials (low-carbon plastic, low-carbon aluminum, low-carbon copper), but also has a complete traceable low-carbon recycling supply chain, starting from raw materials From recycling to product production, a closed cycle is realized.

This supply chain includes recycling plants, concentration plants, dismantling plants, treatment plants, purification plants and regeneration plants. Each stage is strictly inspected to achieve a purity of 98% or above, and has passed TÜV Green Environmental Protection Verification 14021 and Carbon Footprint Verification 14067, life cycle assessment verification 14040 and other international verifications. The PCR materials provided by CRAM are not only comparable to new materials in terms of physical properties, but also have a carbon footprint that is only 1/10 of new materials. This significantly reduces the carbon emissions of corporate carbon inventories (Scope 3/Category 4) and product carbon footprints.

For brands, OEM/ODM and manufacturers, CRAM provides targeted carbon reduction consulting services, providing professional carbon reduction support from project development to product life cycle management. At the exhibition, many companies expressed the difficulties in developing low-carbon products, especially the balance between carbon reduction and physical property stability. With its rich experience in low-carbon technology, CRAM assists customers in accurately introducing low-carbon materials, and provides customized solutions for various needs such as fire protection, anti-static, glass fiber, mineral fiber and other special physical properties to help companies balance technology, cost and efficiency. Strike the ideal balance.

Helping companies achieve net-zero emissions goals

As the world and Taiwan are committed to promoting net-zero emissions by 2050, the specific practices of ESG have received increasing attention. CRAM can reduce the earth's carbon emissions by approximately 322,528 metric tons every year, which is equivalent to the carbon reduction of 1,329 Daan Forest Parks in one year. With this goal in mind, the company works closely with the government of the Republic of China and international green economy advocates to provide low-carbon solutions for the circular economy.

In addition to providing technical support, CRAM is more deeply involved in customers' carbon management processes, providing companies with carbon reduction plans and carbon emission reduction specifications, and signing annual PCR cycle material quantity controls with customers to help companies achieve annual carbon reduction goals. This all-round support allows companies to more effectively respond to carbon inventory challenges, further improve their performance in ESG scores, and enhance their international competitiveness. At the same time, CRAM also develops customized supply chain carbon reduction execution plans for brands and OEMs/ODMs, and is committed to creating carbon value for enterprises, enhancing low-carbon competitiveness, and helping them stand out among ESG indicators.

Low-carbon circular supply chain realizes product closed cycle and net-zero transformation

CRAM has accumulated more than half a century of experience in the field of PCR recycling, which gives us not only technical advantages but also the ability to provide in-depth services to enterprises’ net-zero transformation needs. At this exhibition, CRAM demonstrated a one-stop carbon reduction solution from recycling to regeneration, and discussed with many companies how to effectively realize product closed cycles, as well as the application performance and carbon reduction of product closed cycles in international brands. Effect. Facing the future, CRAM hopes to continue to promote the circular economy, help more companies effectively reduce their carbon footprint, while enhancing their carbon value and international competitiveness, and successfully achieve the goal of net-zero transformation.

CRAM team members all come from recycled materials backgrounds and are trained and certified in carbon inventory and carbon footprint.

Special thanks to the Taiwan Sustainable Supply Association, the Kaohsiung City Government, the Kaohsiung Economic and Trade Development Association, the Resource Recycling Administration of the Ministry of Environment and the Circular Economy Promotion Office for their support, which made the 2024TASS exhibition a success and gave us the opportunity to meet with many distinguished guests. Conduct consultations on practical carbon reduction projects. CRAM will continue to develop low-carbon recycling technology in the future and help global customers achieve the goal of net-zero emissions with innovative and professional services.

DIGITIMES carbon cycle application materials column news >> https://www.digitimes.com.tw/tech/dt/n/shwnws.asp?CnlID=13&id=707562