——Transforming sustainable supply chains requires low-carbon productsofsolution

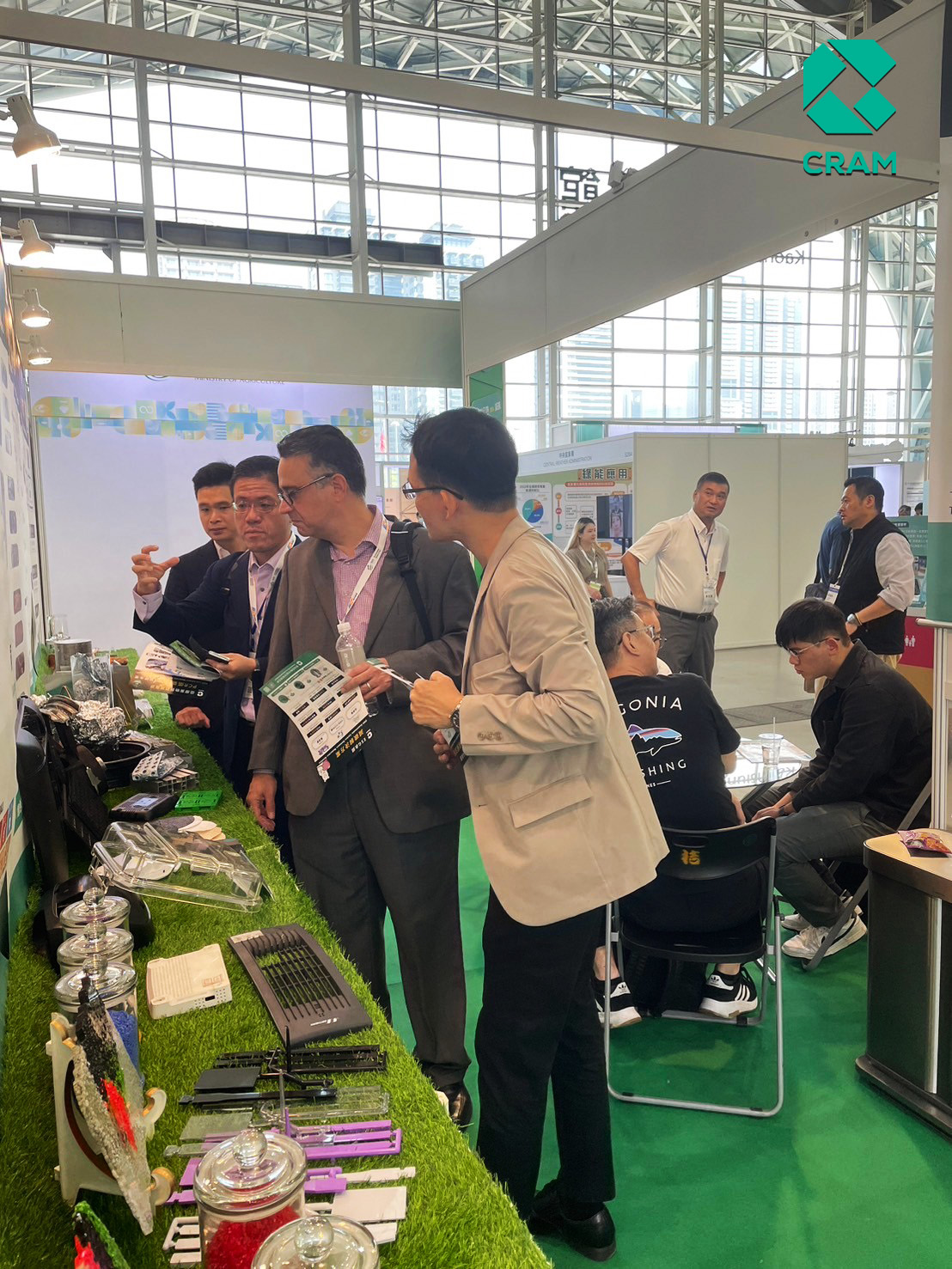

During the TASS exhibition, CRAM had in-depth exchanges with visiting distinguished guests and deeply felt that the manufacturerTransforming a sustainable supply chain, urgent needlow carbon productssolution.

Carbon Cycle Application Materials summarizes 5 key points of manufacturers’ low-carbon transformation needs:

1.Low carbon materialsSources of sustainability:

Manufacturers are looking for stable, certifiedLow carbon recycling materialssource to meet the brand’s needsSustainable supply chainrequirements, and increasingly stringentCarbon emissionsand environmental regulations.

2.carbon footprintTransparency:

Brands and manufacturers need to fully track productscarbon footprint, and provide transparency throughout the supply chainCarbon emissionsinformation to meet both consumer and regulatory requirements.

3.Closed recycling system:

Enterprises achieveNet zero transitionThe goal requires a closed cycle system that can efficiently recycle waste materials and regenerate them into new materials, thereby reducing resource consumption and enabling multiple recycling of materials.

4. Comply with standardslow carbonCertification:

More and more brands and customers are asking suppliers to provide third-party supplierslow carbonCertification (such as TUV certification) to ensure that its materials and products meet environmental standards.

5.Low carbon materialsTechnological innovation:

Enterprises urgently need advancedLow carbon materialstechnology, and cooperate with the research and development of low-carbon products to ensure product quality while reducingCarbon inventorydifficultyCategory threeofCarbon emissions.

Professional consulting services for low-carbon products

CRAM is unique in that it not only provides high-qualityPCR(Post-Consumer Recycled) recycled low-carbon materials (low-carbon plastic, low-carbon aluminum, low-carbon copper), and also has a complete traceable low-carbon recycling supply chain, from raw material recycling to product production, all achieving a closed cycle.

This supply chain includesRecycling plants, concentration plants, dismantling plants, treatment plants, purification plants and recycling plants, each stage has been strictly inspected to achieve a purity of 98% or above, and has passed TÜV green environmental protection verification14021,carbon footprintverify14067, life cycle assessment verification14040Waiting for international verification.

Provided by CRAMPCR materialsNot only is it comparable to new materials in terms of physical properties,carbon footprintOnly 1/10 of new materials, which significantly reduces the cost of the companyCarbon inventory(Category three/category4) Carbon emissions and product carbon footprint.

For brands, OEM/ODM and manufacturers, CRAM provides targetedCarbon reductionConsulting services, from project development to product life cycle management, are providedCarbon reductionProfessional support. At the exhibition, many companies expressed their concern forLow carbon productsdevelopment difficulties, especially inCarbon reductionbalance issue with physical stability.

CRAM is known for its richlow carbonTechnical experience to assist customers in accurate importLow carbon materials, and provide customized solutions for special physical properties such as fire protection, antistatic, glass fiber, mineral fiber, etc. for various needs to help companies achieve an ideal balance between technology, cost and efficiency.